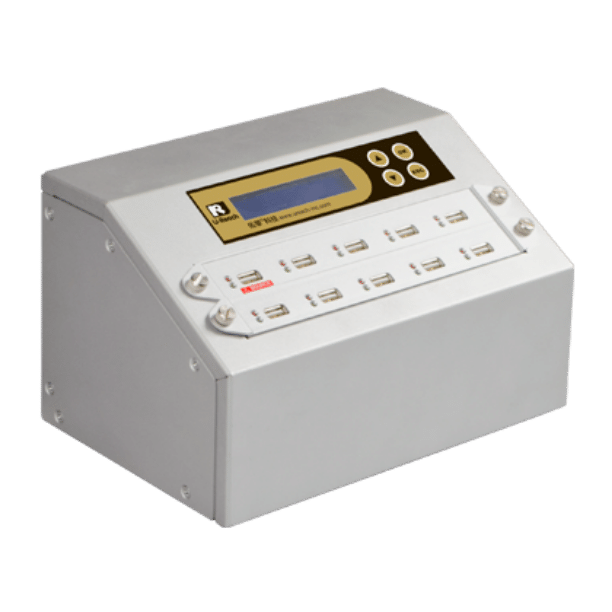

Data Duplicator for Electronic Manufacturing – Why Choose U-Reach

Electronic manufacturing requires fast, accurate, and repeatable data deployment to support production lines, firmware programming, device configuration, and final product testing. U-Reach duplicators deliver the precision, speed, and reliability needed for high-volume EMS, OEM, and ODM environments where consistency is critical.

Secure, Standalone Hardware (No OS, No Hard Drive, No Malware Risk)

U-Reach duplicators operate on FPGA-controlled hardware without an operating system or internal hard drive.

For manufacturing environments, this provides:

Zero risk of viruses, OS crashes, or software corruption

No hidden logs or residual customer data left inside the equipment

A stable, predictable process ideal for production lines and cleanroom environments

This ensures every duplication station remains secure and interference-free on the factory floor.

High-Speed, Parallel Duplication for Mass Production

Manufacturing workflows depend on throughput. U-Reach duplicators are optimized for:

Multi-port parallel duplication

Full-speed, sustained performance even at maximum load

Perfectly identical image replication for every device

This greatly reduces cycle times for flashing SSDs, programming flash media, or loading firmware during assembly or testing.

Bit-by-Bit Copy with CRC & MD5 Verification

Quality and consistency are essential in electronics production. U-Reach ensures every drive receives the exact same data using:

True bit-by-bit imaging

CRC checksum verification

MD5 hash verification for high-assurance data integrity

This safeguards product reliability, lowers RMA rates, and ensures firmware and system images match across every batch.

Supports All Storage Media Used in Manufacturing

Modern electronics rely on multiple storage formats, and U-Reach supports them all, including:

NVMe / M.2 SSD

SATA SSD / HDD

USB drives

SD, microSD, CF, CFast, and more

This flexibility allows a single duplicator to support multiple product types and assembly lines, reducing equipment cost and simplifying workflow.

Built for Continuous, Industrial Operation

Manufacturing requires machines that can operate nonstop. U-Reach duplicators are designed with:

Industrial-grade components

Efficient cooling systems

High-durability connectors

Stable long-run performance

Perfect for 24/7 production environments, repair centers, and high-throughput testing stations.

Production QC Logs & Traceability

Manufacturers must track processes for quality control, customer requirements, and traceability.

U-Reach systems generate detailed duplication logs that record:

Serial numbers of each drive

Pass/fail verification results

Timestamp and port information

Operation settings and method

These logs provide valuable documentation for audits, customer reporting, and internal QA.

UReach Duplicator for

Data Eraser for Electronic Manufacturing – Why Choose U-Reach

In electronic manufacturing, protecting customer IP, preventing firmware leakage, and maintaining strict production cleanliness are crucial. Storage devices used during development, testing, repair, or rework often contain sensitive data that must be permanently removed before reuse or disposal. U-Reach data erasers offer a fast, reliable, and secure solution designed specifically for high-volume EMS, OEM, and ODM environments.

Secure, Standalone Hardware for Controlled Production Environments

U-Reach erasers run on FPGA-based standalone hardware with no operating system and no internal storage.

For manufacturing operations, this provides:

No exposure to OS vulnerabilities or malware

No risk of hidden logs or residual customer data

A fully controlled and isolated erasure environment

This ensures clean, consistent data sanitation across the factory floor.

High-Speed, Multi-Port Erasure for Production Efficiency

Production lines and repair centers often process large volumes of drives. U-Reach supports:

Multi-port simultaneous erasure

Stable top-speed performance

Fast cycle times ideal for continuous manufacturing

This minimizes workflow delays and prevents bottlenecks during rework, testing, or refurbishing.

Certified Erasure Methods for Complete Data Removal

To meet the security and compliance requirements of various manufacturing contracts, U-Reach supports recognized erasure standards such as:

NIST 800-88 Purge/Clear

DoD 5220.22-M

Secure Erase / Sanitize

These methods ensure prototype firmware, test logs, configuration files, and production data are permanently destroyed.

Supports All Storage Media Used in Electronics Production

U-Reach erasers can sanitize the full range of media found in modern electronics, including:

NVMe and SATA SSD

USB flash drives

SD, microSD, CF, CFast

SATA/SAS HDD

This universal compatibility simplifies equipment planning and supports multiple product lines within the same facility.

Tamper-Proof Erasure Reports for QC and Client Audits

Traceability is a fundamental requirement in electronics manufacturing. U-Reach systems provide detailed, exportable erasure reports containing:

Serial numbers

Erasure results

Erasure method used

Timestamp and port details

These reports help fulfill quality assurance processes, ISO compliance, and customer audit requirements.

Designed for 24/7 Industrial Operation

U-Reach erasers are built with industrial-grade components to withstand continuous operation. They are ideal for use in:

Assembly lines

RMA repair centers

Testing labs

Engineering and prototyping environments

This durability ensures long-term performance and reliable data security across the production lifecycle.

UReach Eraser for

Data Duplicator

Data Eraser for Electronic Manufacturing – Why Choose U-Reach

Electronic manufacturing requires fast, accurate, and repeatable data deployment to support production lines, firmware programming, device configuration, and final product testing. U-Reach duplicators deliver the precision, speed, and reliability needed for high-volume EMS, OEM, and ODM environments where consistency is critical.

Secure, Standalone Hardware (No OS, No Hard Drive, No Malware Risk)

U-Reach duplicators operate on FPGA-controlled hardware without an operating system or internal hard drive.

For manufacturing environments, this provides:

Zero risk of viruses, OS crashes, or software corruption

No hidden logs or residual customer data left inside the equipment

A stable, predictable process ideal for production lines and cleanroom environments

This ensures every duplication station remains secure and interference-free on the factory floor.

High-Speed, Parallel Duplication for Mass Production

Manufacturing workflows depend on throughput. U-Reach duplicators are optimized for:

Multi-port parallel duplication

Full-speed, sustained performance even at maximum load

Perfectly identical image replication for every device

This greatly reduces cycle times for flashing SSDs, programming flash media, or loading firmware during assembly or testing.

Bit-by-Bit Copy with CRC & MD5 Verification

Quality and consistency are essential in electronics production. U-Reach ensures every drive receives the exact same data using:

True bit-by-bit imaging

CRC checksum verification

MD5 hash verification for high-assurance data integrity

This safeguards product reliability, lowers RMA rates, and ensures firmware and system images match across every batch.

Supports All Storage Media Used in Manufacturing

Modern electronics rely on multiple storage formats, and U-Reach supports them all, including:

NVMe / M.2 SSD

SATA SSD / HDD

USB drives

SD, microSD, CF, CFast, and more

This flexibility allows a single duplicator to support multiple product types and assembly lines, reducing equipment cost and simplifying workflow.

Built for Continuous, Industrial Operation

Manufacturing requires machines that can operate nonstop. U-Reach duplicators are designed with:

Industrial-grade components

Efficient cooling systems

High-durability connectors

Stable long-run performance

Perfect for 24/7 production environments, repair centers, and high-throughput testing stations.

Production QC Logs & Traceability

Manufacturers must track processes for quality control, customer requirements, and traceability.

U-Reach systems generate detailed duplication logs that record:

Serial numbers of each drive

Pass/fail verification results

Timestamp and port information

Operation settings and method

These logs provide valuable documentation for audits, customer reporting, and internal QA.

UReach Duplicator for

Data Eraser

Data Eraser for Electronic Manufacturing – Why Choose U-Reach

In electronic manufacturing, protecting customer IP, preventing firmware leakage, and maintaining strict production cleanliness are crucial. Storage devices used during development, testing, repair, or rework often contain sensitive data that must be permanently removed before reuse or disposal. U-Reach data erasers offer a fast, reliable, and secure solution designed specifically for high-volume EMS, OEM, and ODM environments.

Secure, Standalone Hardware for Controlled Production Environments

U-Reach erasers run on FPGA-based standalone hardware with no operating system and no internal storage.

For manufacturing operations, this provides:

No exposure to OS vulnerabilities or malware

No risk of hidden logs or residual customer data

A fully controlled and isolated erasure environment

This ensures clean, consistent data sanitation across the factory floor.

High-Speed, Multi-Port Erasure for Production Efficiency

Production lines and repair centers often process large volumes of drives. U-Reach supports:

Multi-port simultaneous erasure

Stable top-speed performance

Fast cycle times ideal for continuous manufacturing

This minimizes workflow delays and prevents bottlenecks during rework, testing, or refurbishing.

Certified Erasure Methods for Complete Data Removal

To meet the security and compliance requirements of various manufacturing contracts, U-Reach supports recognized erasure standards such as:

NIST 800-88 Purge/Clear

DoD 5220.22-M

Secure Erase / Sanitize

These methods ensure prototype firmware, test logs, configuration files, and production data are permanently destroyed.

Supports All Storage Media Used in Electronics Production

U-Reach erasers can sanitize the full range of media found in modern electronics, including:

NVMe and SATA SSD

USB flash drives

SD, microSD, CF, CFast

SATA/SAS HDD

This universal compatibility simplifies equipment planning and supports multiple product lines within the same facility.

Tamper-Proof Erasure Reports for QC and Client Audits

Traceability is a fundamental requirement in electronics manufacturing. U-Reach systems provide detailed, exportable erasure reports containing:

Serial numbers

Erasure results

Erasure method used

Timestamp and port details

These reports help fulfill quality assurance processes, ISO compliance, and customer audit requirements.

Designed for 24/7 Industrial Operation

U-Reach erasers are built with industrial-grade components to withstand continuous operation. They are ideal for use in:

Assembly lines

RMA repair centers

Testing labs

Engineering and prototyping environments

This durability ensures long-term performance and reliable data security across the production lifecycle.